Model No.︰P-F25AC-020G

Brand Name︰PIONEER

Country of Origin︰China

Unit Price︰US $ 5 / pc

Minimum Order︰1 pc

(I) technical parameters:

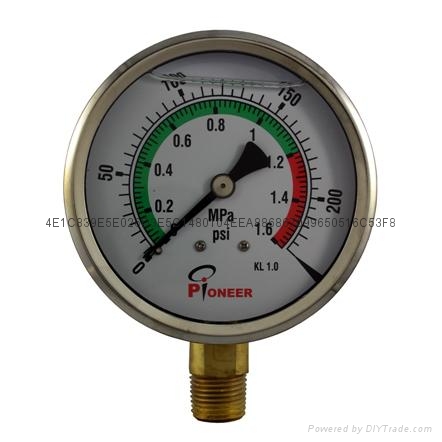

Product name: shock pressure gauge

Product model: P-F25AC-100G

Head diameter: 63mm

Pressure range: 0~10kg (customized)

Surface material: stainless steel shell SUS304

Inner machine material: copper alloy

Connector material: copper alloy

Installation method: radial

Interface thread: 1/4pt

Accuracy grade: 2.5 level

(ii) product description:

Seismic pressure gauge is also called the oil pressure gauge or seismic pressure gauge, for measuring the pressure on copper and copper alloy non-corrosive medium. It is inside the pressure gauge shell injection liquid, to prevent pressure gauges for pressure fluctuations or external earthquake equipment affect compressive strength test, the vibration of strong earthquake and environmental obvious buffering effect. Through to the oil filled in the table, also parts of the machine also has the role of lubrication, and extend the service life of the instrument. It is the most commonly used hydraulic station, hydraulic machinery, sometimes used for industrial pump, if the pressure fluctuation is too big, can choose to add damping the self-contained nail, or add buffer bend at the bottom of the pressure gauge.

The "PIONEER" seismic pressure gauges have a fine appearance, stable quality, can resist the vibration of the working environment and the pulse of the pressure of the medium, and have higher measurement accuracy and superior anti-fatigue performance. It is widely used in petroleum, mining, hydraulic and other industrial fields.

(iii) product features:

1. The shell adopts SUS304 stainless steel, the material is authentic and the corrosion resistance is excellent.

2. The top of the instrument is equipped with explosion-proof pressure hole, which is safe and reliable.

3. Extensive use of space, save the working environment for the use of pressure gauges.

4. Flexible installation mode, easy to remove.

5. The beautiful appearance makes the use of equipment more valuable.

6. The filling medium can be selected according to the user's requirement.

7. A lot of pressure range, can better adapt to customer's requirements.

8. Various materials are available for selection and wide applicability.